For a couple of weeks I’ve been working on upgrading the camera jib that I built a few years ago. The overall steel design will not be dramatically changed. But there will be some improvements in the cable management, digital servos, and inline remote controller. Most of which I do hope to talk about in the future. This portion of the project focused on the cable management. Having the aluminum tubes running through the jib head’s frame will allow several small cables to pass through (BNC, mini-hdmi, RCA, and even power cables. Ideally managing unwanted resistance to the movement of the servo motors.

Here is the original setup with the HVX200.

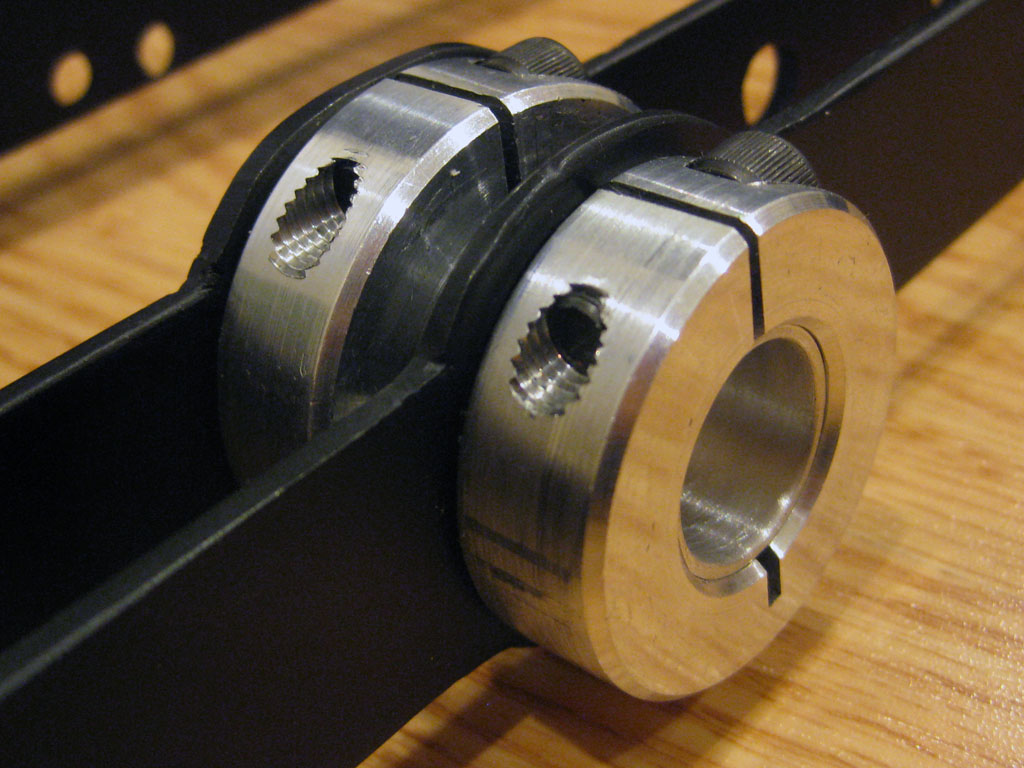

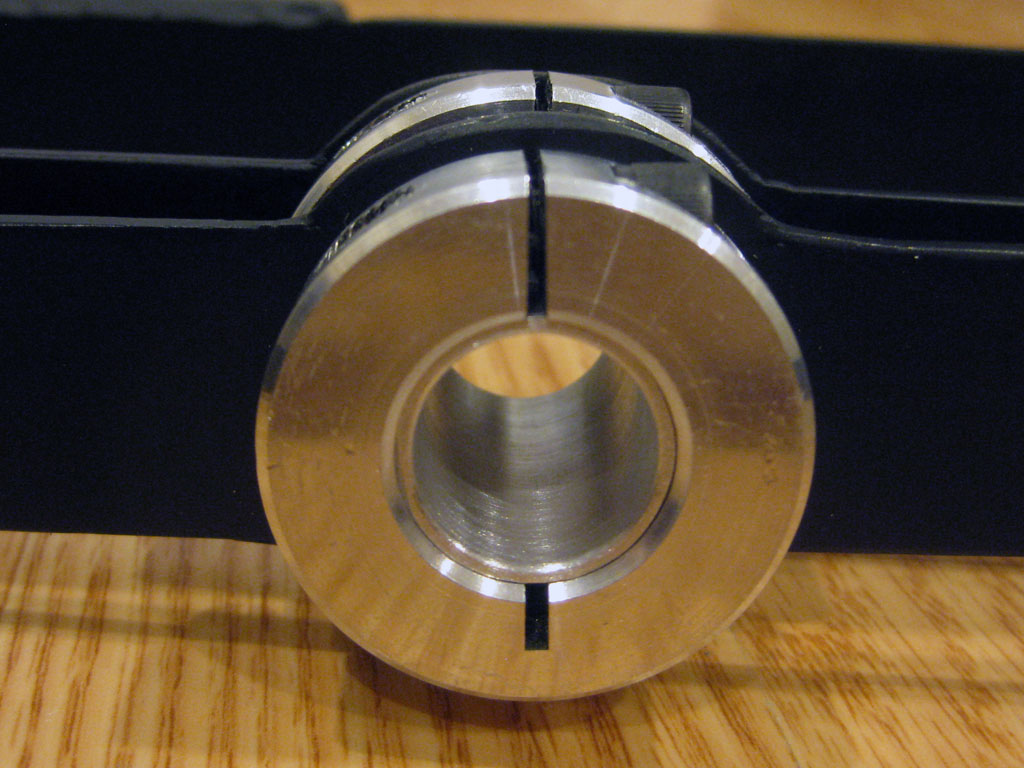

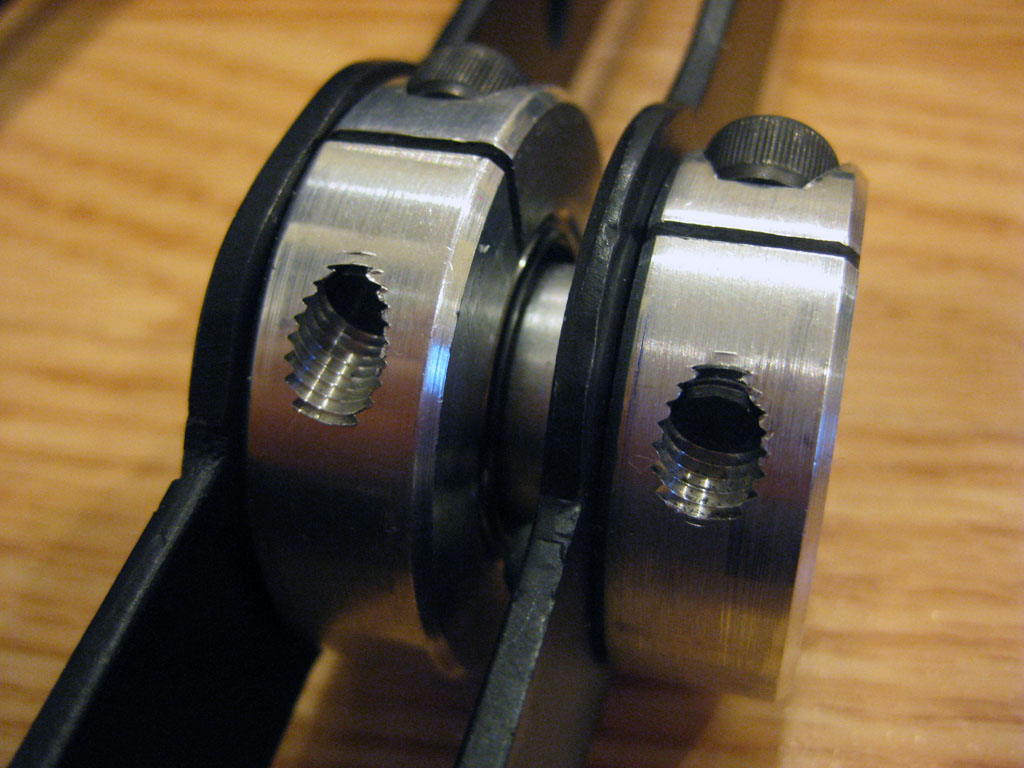

The tubes are 3/4″ OD aluminum with their 3/4″ ID collars to mount them.

This project required 2 special bearings: the roller bearing which rolls outside of the tube…

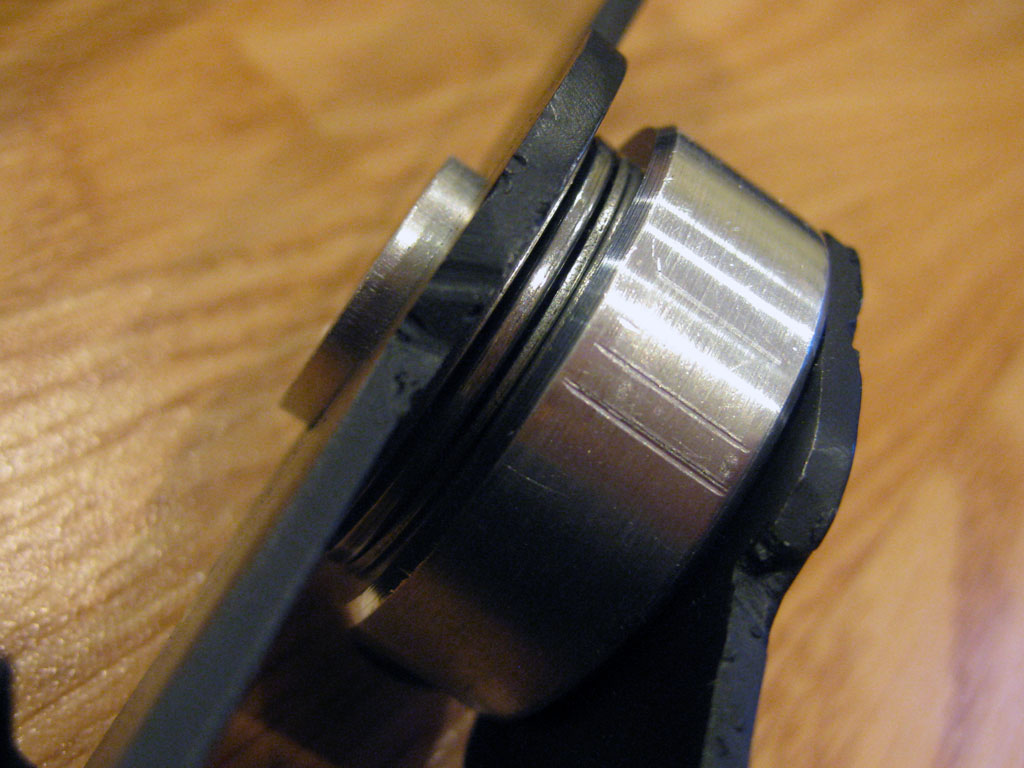

..and thrust bearing supporting the weight of the camera.

March 2, 2011 @ 8:28 pm

Dan, I’ve said it and I’ll say it again: you’re an engineer in your bones and it really shows ;P. Keep up the good work. You’ll probably be designing or improving baby items before too long, hehe :).

March 3, 2011 @ 9:44 pm

First, I thought this was Misono’s post! hehe ¤Öé

March 3, 2011 @ 11:22 pm

haha* This is too technical of a subject matter for me to post about — I could never create something like this!

March 3, 2011 @ 11:22 pm

Impressive, hubby! ¤Öé You are quite the mad scientist. ¤śø